DSC7500A BK

| 成型方式 | 注塑 |

|---|---|

| 特点 | 耐化学性, 刚性, 耐磨性 |

| 成分 | PK 耐磨性 |

-

成分

材料特点DESTONE® DSC7500A 是由羰基和碳氢化合物组成的聚酮制成的结晶工程塑料,具有优异的散热性、导热性、耐磨性、耐化学性和机械强度。

成型条件本产品经除湿后密封,成型前无需干燥,但如果产品含有水分,请在 100℃的温度下除湿至少 3 小时,以确保水分含量保持在 0.05% 以下。

-

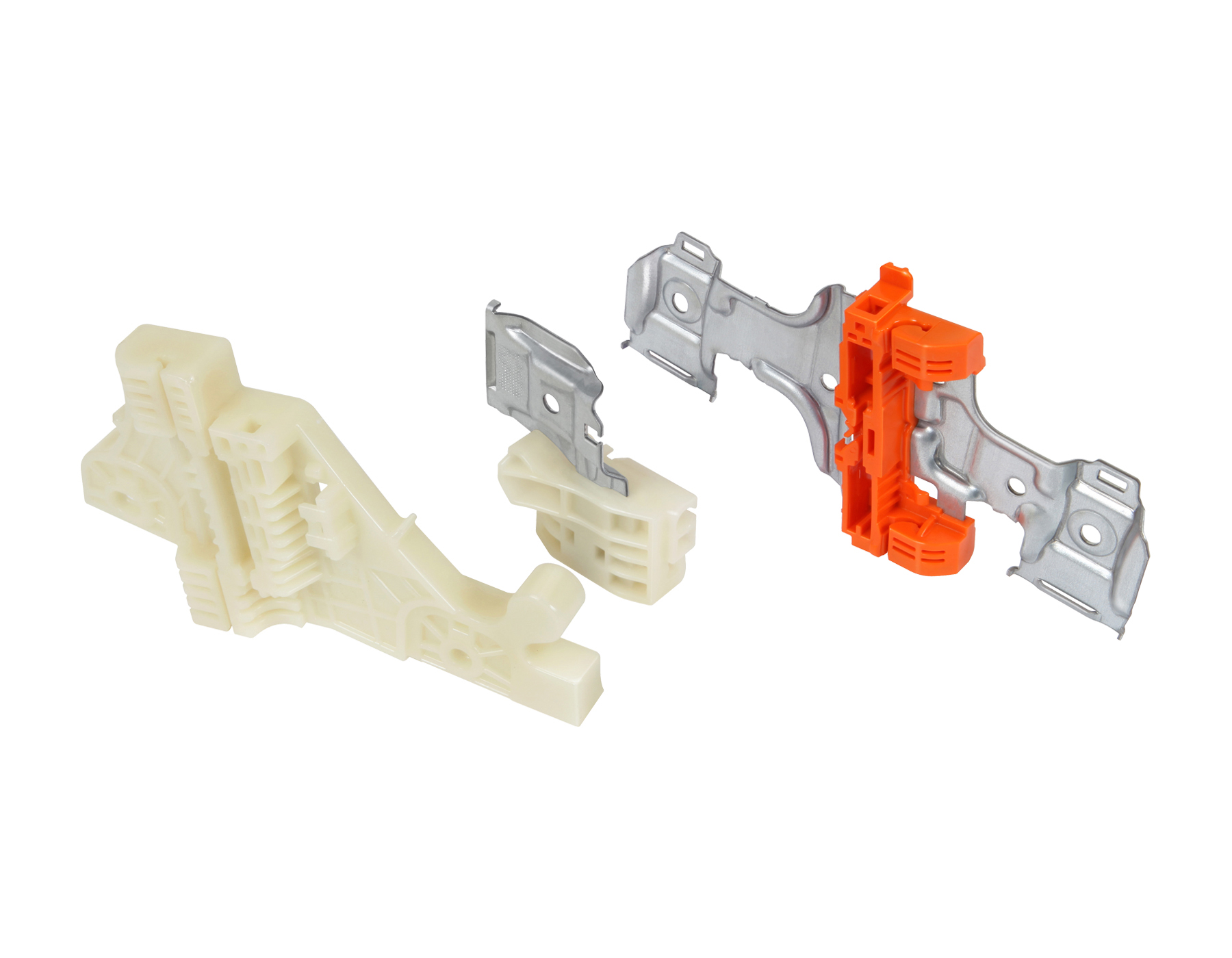

适用领域

-

应用实例

| 分类 | 单位 | 范围 | |

|---|---|---|---|

| 树脂干燥温度 | °C | 80 | |

| 树脂干燥时间 | Hr | 2 ~ 4 | |

| 气缸 | 后部 | °C | 220 ~ 230 |

| 中部 | °C | 230 ~ 235 | |

| 全部 | °C | 230 ~ 240 | |

| 喷嘴温度 | °C | 235 ~ 240 | |

| 材料温度 | °C | 225 ~ 230 | |

| 模具温度 | °C | 40 ~ 80 | |

| 注射速度 | % | 30 ~ 70 | |

| 喷射力 | 1st | % | 30 ~ 70 |

| 2nd | % | 30 ~ 70 | |

| 注塑压力 | % | 20 ~ 40 |

-

1.化学产品和制造商信息

1) Product Name : DESTONE® DSC7500A

annotation) # : an Arabic number (3~ 10)

2) Recommended use of the chemical and restrictions on use

Recommended use of chemical

- For injection molding and extrusion molding

Restrictions on use

- Do not use it for anything other than the recommended purposes

3) Manufacture/Supplier

Company: DESCO CO., LTD.

Address: 24, Gongdan-ro 9-gil, Waegwan-Eup, Chilgok-Gun, Kyeongbuk, Republic of Korea

Tel: +82-54-970-5861 -

2.危害风险

1) Hazard Classification

2) GHS (Globally Harmonized System Classification and labeling of chemicals)

Pictographs: N/A

Hazard statements: N/A

Precautions: N/A

3) Hazard classification does not include other hazard (NFPA)

Health =1, Fire = 1, Reactivity = 0 -

3.成分、含量及相关信息

Chemical Nature CAS No. Composition(%)

------------------------------------------------------------------------------------

1-Propene, polymer with 88995-51-1 ≥ 98

carbon monoxide and ethane

Additives - ≤ 2

* It’s not dangerous generally and a small quantity of additions and impurities aren’t shown, but we can offer it for medical treatment. -

4.急救小贴士

1) Eye contact

- Flush with plenty of water or physiology solution.

2) Skin contact

- Get rid of polluted clothes, accessories and shoes. Wash off in soap or natural detergents using plenty of water.

3) Inhalation

- Escape from polluted place and inhale the fresh air.

4) Ingestion

- No need of first-aid measures. Just vomit get medical attention if person became unconscious.

5) Note to physician and first-aid

- No special antidote. Supportive therapy should be used according to symptoms. -

5.发生爆炸、火灾时的应对措施

1) Proper (and improper) fire extinguisher

- Suitable: CO2, water, powder, general foam

- Not suitable: N/A

2) Specific hazards arising from the chemical

- Irritant smoke may cause such as Carbon monoxide (CO), NOx, Halides and etc.

3) Protective equipment and precautions for firefighting

- In case of Fire, spray the fire extinguisher toward the ignition point after securing a safe distance

- If you do not have fire extinguishers, sand for fire and fire hydrant may be used.

- People around the fire evacuate to safe area.

- During a fire, harmful gas can be caused by combustion and decomposition of substances. -

6.泄漏时的应对方法

1) Precautions and equipments for personal protection

- Do not inhale dust and vapor during operation.

- Immediate disposal to prevent risk of slipping.

2) Precaution for environmental protection

- N/A

3) Purification or removal methods

- According to Industrial Waste Disposal regulation, move to approved place. -

7.处理和储存

1) Safe handling

- Storage and handling in accordance with regulations and the law in force.

2) Safe storage

- Stare in a dry place and away from incompatible materials. -

8.防止接触和个人防护设备

1) Standard of chemical exposure, standard of biological exposure and etc.

Internal regulations: N/A

ACGIH regulations: N/A

Standard of biological exposure

2) Appropriate engineering controls

- It needs air exhauster which can remove dust and gas during work. If necessary, using a qualified mask for dust and organic solvents

3) Personal protective equipment

Respiratory Protection

- The operator should wear a mask for anti-dust

Eye protection

- Wear safety goggles and install an eye wash and emergency wash facilities.

Hand protection

- Injection workers should wear gloves, arm guards, and heat-resisting equipment.

Body protection

- After handling, wash clean -

9.物理化学特性

1) Appearance: Specified color and granulate form

2) Smel: Nearly odorless

3) Threshold value: N/A

4) PH: 6.5 ~ 7.5 at 20℃

5) Melting point/freezing point: >130℃

6) Boiling point/Boiling range: N/A

7) Flashing point: No flash occurred under 93℃ (Rapid equilibrium method)

8) Evaporating rate: N/A

9) Flammability (solid, gas): Burning rate: < 0.7 mm/s

※ UN TDG test & criteria – Test N1

10) Upper/lower bond of flammability or explosive: No self-reaction hazard.

※ UN TDG test & criteria – Test E3

11) Vapor Pressure: N/A

12) Solubility: Insolubility in water

13) Vapor pressure: N/A

14) Specific gravity: 1.21 ~ 1.25 at 23℃

15) n-Octane/water partition coefficient: N/A

16) Spontaneous ignition temperature: N/A

17) Pyrolysis temperature

18) Viscosity: N/A

19) Molecular weight: N/A -

10.稳定性和反应性

1) Chemical stability and the possibility of adverse reactions: stable under normal temperature pressure

2) Conditions to avoid

- Heat, flames, sparks and other sources of ignition

3) Substances to avoid

- Acid, A base, An oxidizing agent

4) Harmful substances at decomposition

- Toxic carbon compounds can be released -

11.有关毒性的信息

1) Information for exposed route with high possibility: N/A

2) Information for health hazard

Acute toxicity: N/A

Skin corrosiveness or irritation: N/A

Serious eye damage or irritation: N/A

Respiratory sensitization: N/A

Skin Sensitization: N/A

Carcinogenic: N/A

Mutagenicity: N/A

Particular target of toxicity (Single exposure)

Particular target of toxicity (Repeated exposure)

Inhalation Hazards: N/A -

12.环境影响

1) Ecotoxicity: N/A

2) Persistence and degradability: N/A

3) Transferability in soil: N/A

4) Other adverse effects: N/A -

13.废弃时的注意事项

1) Methods of disposal: Handle by precautions specified in the Wastes Control Act

2) Disposal Considerations: Handle by precautions specified in the Wastes Control Act -

14.运输所需信息

1) UN number: N/A

2) UN Proper name of shipping: N/A

3) Hazard class of Transit: N/A

4) Container grade: N/A

5) Marine pollutants: N/A

6) Special Safety measures the user need or need to know about transportation or means of transportation

- Emergency measures for fire: N/A

- Emergency measures for Outflow: N/A -

15.法律及监管状况

1) Restriction by industrial safety and health Act: N/A

2) Restriction by Registration and Evaluation, Etc. of Chemical Substances Act: N/A

3) Restriction by Safety Control of Dangerous Substances Act: N/A

4) Restriction by Wastes Control Act: N/A

5) Restriction by domestic and international law

Domestic restriction

- N/A

Foreign restriction

- American Management Information (OSHA regulation): N/A

- American Management Information (CERCLA regulation): N/A

- American Management Information (EPCRA 302 regulation): N/A

- American Management Information (EPCRA 304 regulation): N/A

- American Management Information (EPCRA 313 regulation): N/A

- American Management Information (Rotterdam Convention materials): N/A

- American Management Information (Stockholm Convention materials): N/A

- American Management Information (Montreal protocol materials): N/A

- EU classification information (Decided fractionation result): N/A

- EU classification information (Dangerous substance): N/A

- EU classification information (Safety notice): N/A -

16.其他参考事项

1) Source of data

This MSDS was edited from DESCO Co., Ltd. based on the data of Korea

Industrial Safety Corporation according to Industrial Safety and Health

Act of Article 41 and announced by Ministry of Labor Notice No. 96-12.

2) Creation date: 1. Nov. 2016

3) The number and final date of revision: 8 times / 1th November. 2023

4) Others

This documentation was made out based on our piled up experience and

knowledge of our R&D center. It is suggested that this information

contained in this document can be used for General indication. Therefore,

you should not construe it as product specifications, and you should do

appropriate test before you considering your conditions for newly

applications.

家电

家电

工业产品

工业产品