DESTONE

DSC7500G6 BK(W)

| Molding method | Injection molding |

|---|---|

| Features | Chemical Resistance, Rigidity, Dimensional Stability, Heat Resistance |

| Ingredients | PK GF30% |

-

Ingredients

Material characteristicsDESTONE® DSC7500G6 is a polyketone composed of carbonyl groups and hydrocarbons with 30% glass fiber reinforcement and is a crystalline engineering plastic with excellent mechanical properties, good rigidity, heat resistance, chemical resistance, and dimensional stability.

Molding conditionThis product is sealed after dehumidification and does not require additional drying prior to molding. However, if the product contains moisture, we recommend dehumidifying it for at least 3 hours at a temperature of 80°C to ensure that the moisture content remains below 0.05%.

-

Application Part

-

Application Examples

| Property | Item | Condition | Method | Unit | Value |

|---|---|---|---|---|---|

| Physical | Water Absorption | 23°C, 50% RH | ISO 62 | % | 0.4 |

| Specific Gravity | 23°C | ISO 1183 | - | 1.46 | |

| Mold shrinkage | Flow, 60 X 60 X 2mm | ISO 294-4 | % | 0.3 | |

| Cross-flow, 60 X 60 X 2mm | ISO 294-4 | % | 0.51 | ||

| Mechanical | Tensile Strength | 5 mm/min, 4mm | ISO 527 | MPa | 140 |

| Elongation | 5 mm/min, 4mm | ISO 527 | % | 3.2 | |

| Tensile modulus | 1 mm/min, 4mm | ISO 527 | MPa | 9300 | |

| Flexural Strength | 2 mm/min, 4mm | ISO 178 | MPa | 217 | |

| Flexural Modulus | 2 mm/min, 4mm | ISO 178 | MPa | 8000 | |

| Charpy Impact Strength | Noched, 4mm, 23°C | ISO 179 | kJ/m2 | ||

| IZOD Impact Strength | Noched, 4mm, 23°C | ISO 180 | 13 | ||

| Rockwell Hardness | R-Scale | ISO 2039-2 | - | ||

| Thermal | Melting Point | ISO 11357-3 | °C | 220 | |

| HDT(1.8MPa) | 4mm, Flatwise Unannealed | ISO 75 | °C | 215 | |

| HDT(0.46MPa) | 4mm, Flatwise Unannealed | ISO 75 | °C | 220 | |

| Flammability | UL 94 | - | HB | ||

| Electrical | Volume resistivity | IEC 60093 | Ohm | ||

| Dielectric Constant(10^6HZ) | - | ||||

| Dielectric Strength | IEC 60243-1 | KV/mm | |||

| ARC resistance | Sec |

| Property | Unit | Range | |

|---|---|---|---|

| Resin Drying Temperature | °C | 80 ~ 100 | |

| Resin Drying Time | Hr | 3 ~ 5 | |

| Cylinder | Rear | °C | 220 ~ 230 |

| Middle | °C | 230 ~ 235 | |

| Front | °C | 230 ~ 240 | |

| Nozzle Temperature | °C | 230 ~ 240 | |

| Resin Temperature | °C | 225 ~ 230 | |

| Molding Temperature | °C | 40 ~ 80 | |

| Speed | % | 30 ~ 70 | |

| Pressure | 1st | % | 30 ~ 70 |

| 2nd | % | 30 ~ 70 | |

| Holding Pressure | % | 20 ~ 40 |

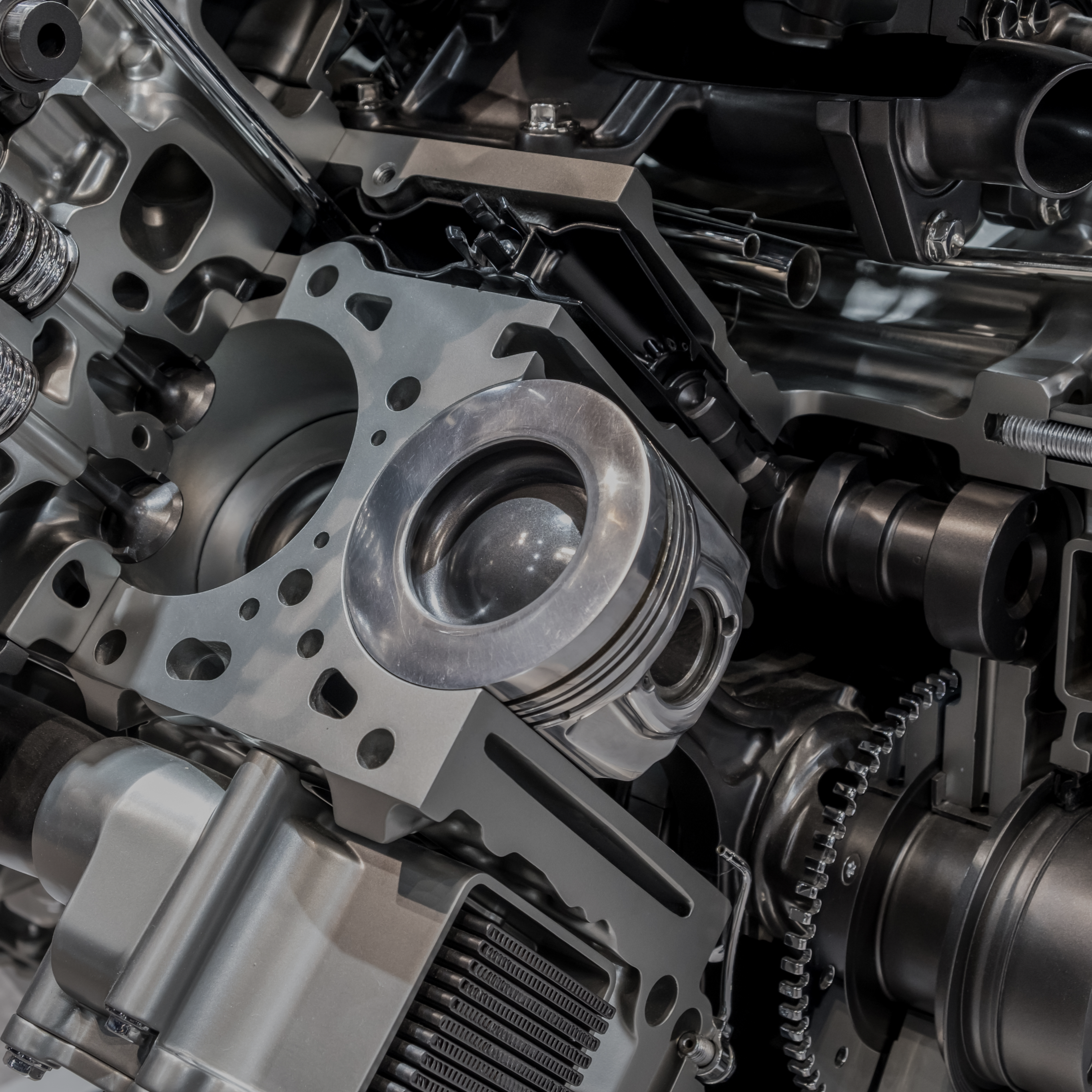

Powertrain

Powertrain

Chassis

Chassis

EV

EV

Industrial Products

Industrial Products